You are here: English > Cold Chain > Cold chain with crates

Crates are used to transport temperature sensitive products like chilled or frozen foods or pharmaceuticals or medicines meaning that they are part of a temperature controlled supply chain or cold chain. When crates are used in a cold chain they can be used in an active or passive cooling system. When an active cooling system is used, the crate is unprotected and placed in a temperature controlled environment where an electrical or mechanical cooler engine is cooling or heating the air surrounding the crates and the goods. When an active cooling system is used it becomes very important that the cold air can float between the crates so the goods in the crates get the temperature they require. An alternative to this active cooling is a passive cooling system meaning that an insulation material, single use or multiple use, is placed on the inside or the outside of the crate to protect the temperature of the goods against unwanted external or outer temperatures. In this case each crate can be insulated individually or can be insulated per product or temperature group. Which of both cooling systems is used is depending on a number of items like costs or prizes, logistic processes, required temperatures, duration of the transport or protection, etc...

Advantages of passive cooling when using crates in a fine distribution cold chain

Crates are often used in fine distribution systems, meaning that small volumes are delivered at each customer. A certain customer gets the order volume of for example one or two crates. This type of small distribution can be seen in the distribution of pharmaceuticals and medicines to the pharmacy where the volume of one or two crates are delivered per pharmacy or in the home delivery of foods where also only one or two crates are delivered at each customer. The transporter who is delivering these crates has therefore a lot of different customers in his van or truck and has a lot of delivery addresses. If all the products, which need to be delivered, have the same temperature, the van or truck can be equipped with an active cooling system cooling the complete load and all the crates for all the customers, yet this active cooling can create only one certain temperature. Is the products in the crates have different temperatures, an active cooling system becomes a problem seeing the cooling engine can only create one temperature. In such cases it would be advisable to implement passive cooling systems where the crates are individually insulated meaning that the temperature of the products in the crate are protected against external temperatures so the temperature of the products remains the same for as long as possible, depending on the insulation quality of the insulation material. A passive cooling has also the advantage that no CCP’s (Critical Control Points) will appear which could create temperature fluctuations. These fluctuations can appear with active during the unloading of the goods from the van to the pharmacy, opening the doors of the van or truck, etc… Another advantage of passive cooling is that products with different temperatures can be transported in one van or truck. Seeing each crate is individually insulated, each crate can contain a certain product or temperature group. Also smaller insulation packaging can be developed so one crate can have two or three different temperatures. The big advantages of passive cooling explains the reason why more and more companies are combining active with passive cooling systems and techniques to make sure that the cold chain or temperature controlled supply chain is completely closed, insuring the quality of the products.

Crates are often used in fine distribution systems, meaning that small volumes are delivered at each customer. A certain customer gets the order volume of for example one or two crates. This type of small distribution can be seen in the distribution of pharmaceuticals and medicines to the pharmacy where the volume of one or two crates are delivered per pharmacy or in the home delivery of foods where also only one or two crates are delivered at each customer. The transporter who is delivering these crates has therefore a lot of different customers in his van or truck and has a lot of delivery addresses. If all the products, which need to be delivered, have the same temperature, the van or truck can be equipped with an active cooling system cooling the complete load and all the crates for all the customers, yet this active cooling can create only one certain temperature. Is the products in the crates have different temperatures, an active cooling system becomes a problem seeing the cooling engine can only create one temperature. In such cases it would be advisable to implement passive cooling systems where the crates are individually insulated meaning that the temperature of the products in the crate are protected against external temperatures so the temperature of the products remains the same for as long as possible, depending on the insulation quality of the insulation material. A passive cooling has also the advantage that no CCP’s (Critical Control Points) will appear which could create temperature fluctuations. These fluctuations can appear with active during the unloading of the goods from the van to the pharmacy, opening the doors of the van or truck, etc… Another advantage of passive cooling is that products with different temperatures can be transported in one van or truck. Seeing each crate is individually insulated, each crate can contain a certain product or temperature group. Also smaller insulation packaging can be developed so one crate can have two or three different temperatures. The big advantages of passive cooling explains the reason why more and more companies are combining active with passive cooling systems and techniques to make sure that the cold chain or temperature controlled supply chain is completely closed, insuring the quality of the products.

Crates for cross-dock applications

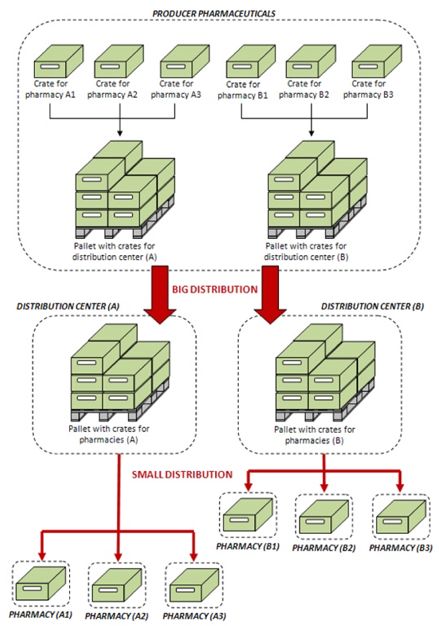

Working with crates and a passive cooling technique also offers the possibility to create a cross-dock application in which the preparation of the goods can be lifted-up higher in the supply chain or cold chain. Where now the crates are filled at the distribution center, the crates could be filled on a customer-level at the producer, leaving the distribution center with only a cross-dock formula which saves a lot of handling and costs. Below is shown an overview of a possible cross-dock formula for the distribution of pharmaceuticals which can also be used for the food industry.

Crates sealing techniques

When crates are used in a supply chain, the question is what will happen if the crate with the goods is delivered at the customer and this customer is not at home or is not able to accept the goods? In this case the crate with the goods can be taken back to the sender or can be left at the doorstep of the customer. If situation two is the best option the crates can be foreseen with sealing techniques to prevent the goods from being stolen. This sealing technique can also be used when passive cooling is used for temperature sensitive goods. In this case the insulation material can be sealed with several sealing techniques so the goods are protected.