EPS Products

- EPS thermal Pallet shippers

- EPS thermal Folding boxes

- EPS thermal Transport boxes

EPS Manufacturing

- Temax EPS Manufacturing

Usage of thermal pallet shippers

EPS Polystyrene insulated thermal pallet shippers are used for the temperature protection of time-temperature sensitive products such as pharmaceuticals or food products during transport or storage. The EPS pallet shippers are manufactured out of Polystyrene, called EPS, which is a light weight insulation material. The thermal pallet shippers offer protection against hot or cold temperatures in which the thermal performance is depending on the temperature situations, conditions and thermal energy exchange.

Temax EPS thermal pallet shipper with thermal seal

The company Krautz Temax has invested in special machines to produce EPS Polystyrene pallet shippers. All pallet shippers can be produced tailor made according to the wishes and specifications of the customer. Unique on the Temax thermal pallet shippers is the thermal seal at the closure. This thermal seal comes automatically into action when the shipper plates are pressed to close. The goal or purpose of the thermal seal is to prevent any temperature risks due to a bad closing of the operator which appears in standard shippers. Due to the thermal seal, thermal bridges, where air can float in our out the pallet shipper, are completely avoided.

BIO based EPS Polystyrene

The company Krautz-Temax has the possibility to manufacture BIO based EPS for producing BIO-degradable EPS pallet shippers and boxes.

User instructions - Protocol pictures

The pictures below show how the Temax Pallet shipper is created. The pallet shipper in the pictures is equipped with special spaces for cardboard boxes filled with gel packs or PCM "Phase Change Materials".

Bottom plate of pallet shipper on pallet

Bottom plate of pallet shipper on pallet

Placing side panel on bottom plate

Placing side panel on bottom plate

THERMAL SEAL connection side-bottom

THERMAL SEAL connection side-bottom

No thermal bridge - NO risks

Back panel on bottom and side panel

Back panel on bottom and side panel

THERMAL SEAL - side + bottom

Boxes gelpacks or PMC in side panel

Boxes gelpacks or PMC in side panel

Boxes gelpacks or PMC in back panel

Boxes gelpacks or PMC in back panel

Boxes Gelpacks - PCM on bottom panel

Boxes Gelpacks - PCM on bottom panel

Loading goods on gelpack boxes

Loading goods on gelpack boxes

Boxes gelpacks or PCM on top of products

Boxes gelpacks or PCM on top of products

Placing side panel + THERMAL SEAL

Placing side panel + THERMAL SEAL

Boxes gelpacks or PCM in side panel

Boxes gelpacks or PCM in side panel

Placement front panel

Placement front panel

THERMAL SEAL - bottom and side panels

THERMAL SEAL - bottom and side panels

Boxes gelpacks or PCM in front panel

Boxes gelpacks or PCM in front panel

Placement top panel

Placement top panel

THERMAL SEAL : top + sides + front + back

THERMAL SEAL : top + sides + front + back

READY for transport

READY for transport

UNIQUE - THERMAL SEAL

All panels are automatically connected to each other by a pressed thermal seal to prevent possible thermal bridges = NO cold or warm air can float in the box.

NO TEMPERATURE RISKS due to bad or incorrect usage

- Patented System -

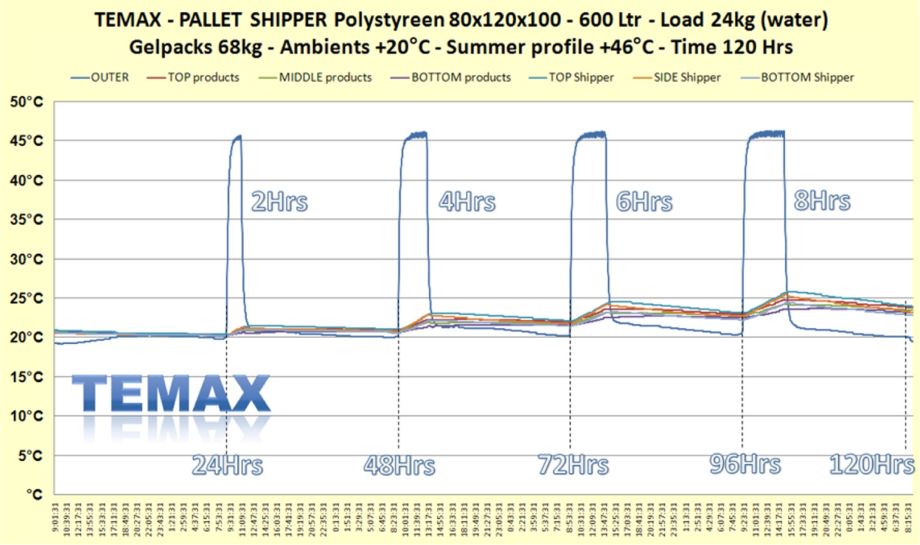

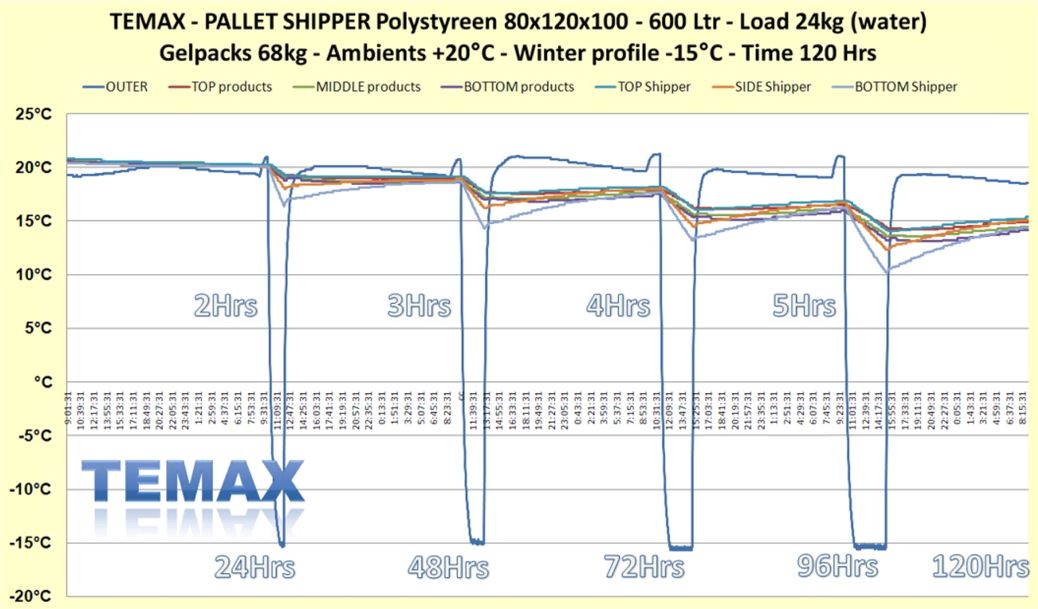

Temperature tests

The Temax EPS Polystyrene pallet shipper has been tested and qualified according to the Temax temperature performance tests. All test results and qualification reports are available on request.

TEST 1 = SUMMER profile - Ambient Pharmaceuticals (20°C) - Airfreight TARMAC simulation

TEST 2 = WINTER profile - Ambient Pharmaceuticals (20°C) - Airfreight TARMAC simulation

Thanks for your visit at our website.

More information on next update.