Thermal covers roll containers

- BI-FOLD - thermal cover

- Middle Closure - thermal cover

- Door closure - thermal cover

- Q-Fold - thermal cover

- No-Condens - thermal cover

- Cross-dock packaging

- Storage systems for covers

Thermal containers

- Mobi-Box thermal container

- Bi-temp thermal container

Usage of thermal insulated covers for roll container with folding door

The insulated cover with door is used to maintain the temperature of temperature sensitive or temperature controlled goods like chilled, refrigerated or frozen foods which are loaded on a roll container. This insulated cover is produced with a door which folds upwards on the roof of the insulated cover. This insulated cover is mostly used when the cover stays on the roller container at all times. Also at the customer. The big advantage is that the food products on the roller container are also temperature protected while remaining at the customer. The roller container and the insulated cover are picked-up at the next transport. Another advantage is that the insulated cover does not need to be handled separately from the roller container. Due to the door the front side can totally be opened so the cover can stay on the roller container during loading and unloading the goods from the roller container. All kind of temperature sensitive food products as fish, meat, salads, vegetables, fruit, frozen food etc can be temperature protected and transported with this insulated cover. Also pharmaceutical products and medicines can be protected and transported.

Advantage = The cover has a door opening = the cover can remain on the roll container during loading unloading

Disadvantage = The cover has two closures = two possible open-convection-flows - thermal bridges or cold bridges

Technical specifications of the thermal cover with folding door

The thermal cover or insulated cover with folding door is produced tailor made according to the wishes of the customer. The thermal covers can be produced - manufactured according to required dimensions, colors, models, required insulation quality etc. If you have special requests, just let us know.

Temperature characteristics

Preservation and stabilization of the product temperature

The thermal covers with folding door or insulated covers are used to preserve or stabilize the temperature of the products, which are protected by the thermal cover, as long as possible. The time that the temperature can be preserved of stabilized, or the speed of temperature increase or decrease, is depending on the insulation quality. Thermal covers or insulated covers with middle closures are manufactured with a certain Temax insulation material which have a certain insulation quality (R-value or U(k)-value). The higher or thicker the insulation quality, the longer the time of temperature preservation or the slower the speed of temperature change of the products inside the thermal cover.

External convection flows due to open thermal bridges – cold bridges

Next to the insulation quality of the thermal cover with folding door, the stability or deviation speed of the temperature of the product is also depending on the presents of open thermal bridges or open cold bridges on the thermal cover and packaging set-up. Open thermal bridges are locations in the design or set-up of the thermal cover where an external convection flow (air flow) can exist which has a very big impact on the speed of temperature change. It is therefore very important that open thermal bridges are avoided at all times.

Adding extra thermal energy generators - Gel Packs – Dry Ice – PCM’s Phase Change Materials

When conditioned or time-temperature sensitive products are protected from external temperature influences with a passive cooling systems such as thermal covers with middle closure systems, the goal is to purely use the available thermal energy of the products to maintain and stabilize the temperature of the products as long as possible. As we know, the result of this stabilization is depending on the insulation quality of the thermal cover combined with possible convection flows and the thermal energy of the products combined with the temperature difference (inside-outside). If the temperature cannot be maintained according to the preferred time-frame, the time can be extended by increasing the available thermal energy. This extra energy can be generated by all kind of passive cooling systems such as gel packs – ice packs – dry ice – PCM’s Phase Change Materials.

Insulating the bottom of the pallet

Most roller containers have bottoms which are not completely closed so a convection flow (air flow) can appear meaning that the air can flow through these openings. Therefore it is very important to seal or insulate the bottom of the container before loading the chilled or frozen products. An insulated bottom will increase the temperature results significant. To insulate the bottom a on-way use insulation or cardboard can be used.

Air in the roll container = negative effect on the available thermal energy

When roll containers are filled with conditioned products, it can happen that the roll container is not completely filled. Yet the roll containers have sidebars which stand higher than the filled goods. This means that lots or air can go into the roll container when the thermal cover is placed over the side-bars. Therefore it is very important that this air is kept to a minimum or an insulated blanket is being placed on top of the goods to protect it from the air above. Also it is important to bring-on the cover in the cold storage room so the air above the goods is the same as the temperature of the goods. Hot air combined with chilled products will have a negative temperature result.

Thermal equilibrium: Always remember that two different temperatures combined in a single thermal packaging system will create a natural thermal equilibrium in which a mutual temperature is created. The final temperature is depending on the thermal energy of each individual product or substance.

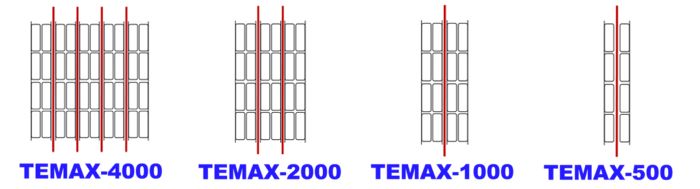

Insulation qualities