What are reefer containers

Reefer containers or refrigerated containers are special developed sea containers which are used to transport time-temperature sensitive products over sea, road and rail. To make this kind of conditioned transport possible, the reefers are especially constructed with insulated panels and cooler engines for cooling or heating conditions (standard -25°C to +30°C). This way they are able to create and maintain a certain pre-set temperature environment according to the quality requirements of the loaded products. Reefers offer an ideal temperature controlled transport system for over-sea supply chains, yet there is a consideration to be made.

Temperature excursions at unplugged locations

Although reefer containers offer a stable and automated temperature condition, they are not completely perfect in their temperature management. This due to the interruption of power in the cold chain. When cooler engines (electrical or diesel powered) are electrically powered, the reefer must be connected to a power unit on the vessel in order to function. As soon as the reefer container is “unplugged”, meaning that there is no power connection, the cooler engine is not functioning and the temperature of the outer environment will start to penetrate in the container contaminating the temperature and quality of the loaded products.

Unplugged situations, where the power is not available, can be noticed at overload locations where the reefer container is transferred from the truck to the harbor to the sea vessel and vice versa. These are typical locations where reefer containers in general experience temperature problems. The combination of exposure time and temperature of the environment at the “unplugged” location will determine the impact of the temperature contamination and risks to the products as shown in the following drawings.

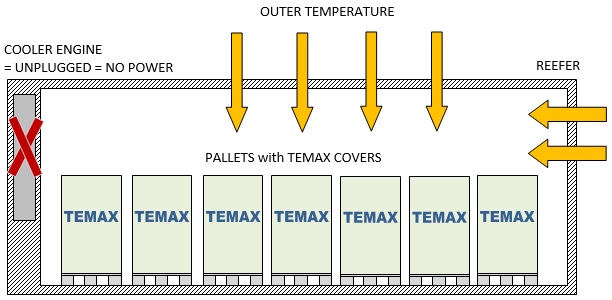

Drawing 1 = Unplugged reefer = START of UNPLUGGED CONDITION

Outer temperature will start to penetration through the reefer walls

Penetration impact / product risks = depending on insulation quality of reefer + time of exposure + outer temperature

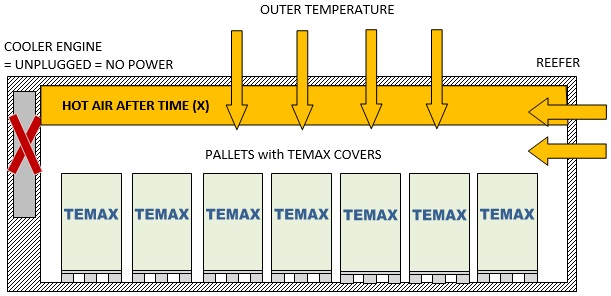

Drawing 2 = Unplugged reefer = UNPLUGGED TIME (X)

HOT air that has penetrated in the reefer will start to rise upwards against the roof

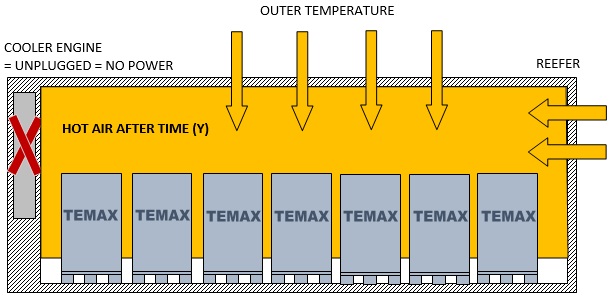

Drawing 3 = Unplugged reefer = UNPLUGGED TIME (Y)

HOT air in the reefer has reached the products = QUALITY RISKS

SOLUTION = Use thermal covers to extent exposure time + minimze quality risks

Thermal covers and blankets for temperature protection at unplugged locations

When reefer containers are used for very temperature sensitive products such as pharmaceuticals with temperature range (+2°C to +8°C) where the temperature is very limited in acceptable heating or cooling without quality impact, the unplugged location can be disastrous for the temperature of these products. Multiple case studies and tests have shown that temperature loggers register too hot or too cold temperatures at these unplugged locations triggering various alarms on quality issues.

In order to offer a solution for these unwanted temperature conditions, thermal covers can be used to protect the pallets inside the reefer. The goal of the thermal cover is to offer temperature protection during the unplugged location reducing or even avoiding any temperature risks or excursions during the unplugged condition. The praxis has shown a very successful usage of thermal covers in reefer transports in which the thermal capacity of the cover determines the time-temperature conditions of the unplugged condition. The higher the thermal quality of the cover, the longer the time or the higher the temperature of the outer environment can be before any product quality damages occur.

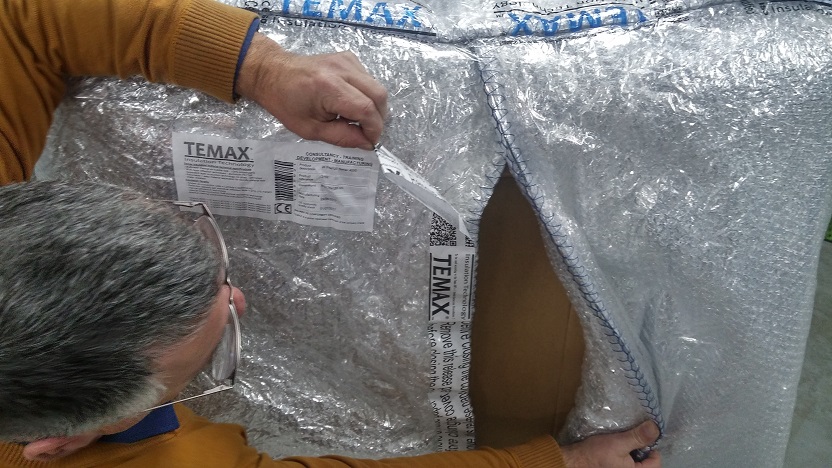

The pictures below show the protocol - user manual for implementing TEMAX thermal covers in reefer containers.

1. Pallet with time-temperature sensitive products

2. Open the cover and pull over the pallet

3. Adjust so the cover corners = pallet corners

4. Remove protective film from double sided tape closure

5. Pull and stretch the cover cosure - press on the tape

6. Adapt height cover = height pallet

7. Tape the overlap closure - No air in or out

8. Ready for transport

IMPORTANT

When thermal covers or thermal blankets are used to insulate pallets in reefers, it is very important that the thermal cover does not block the airflow of the reefer underneath the pallet. Always make sure that the airflow of the reefer (cooler engine) can flow unblocked underneath the pallet.

Thanks for your visit at our website.

More information on next update.