You are here: English > Products > Remax

What is REMAX reflection insulation foil - reflective air bubble foil

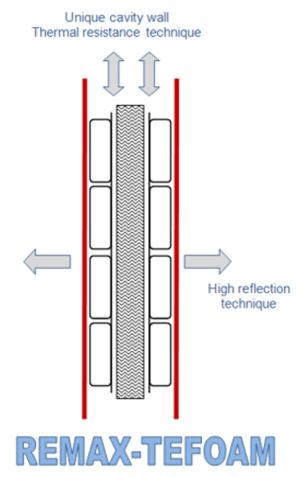

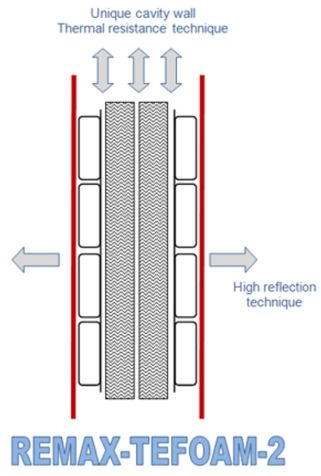

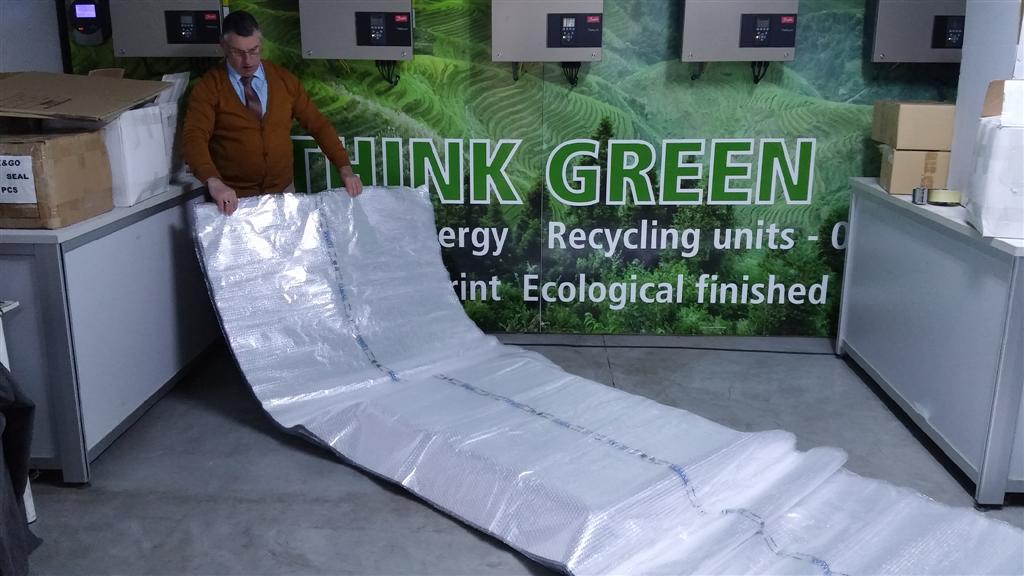

REMAX is a brand name of the company Krautz-Temax and stands for a range of insulation foils in which high reflective foils are integrated. The REMAX insulation foils are composed out of reflection materials and thermal bubble foils which can be extended by insulation foam to increase the required insulation quality.

In the manufacturing of REMAX foils, the reflective foils are laminated to the thermal bubble foil creating a single foil system. It is noticeable that due to the laminating process, the Remax foils are more difficult to recycle than the loose-layer Temax insulation foils.

Remax thermal specifications

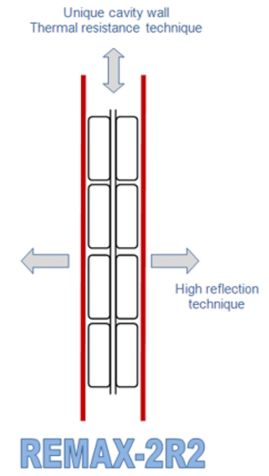

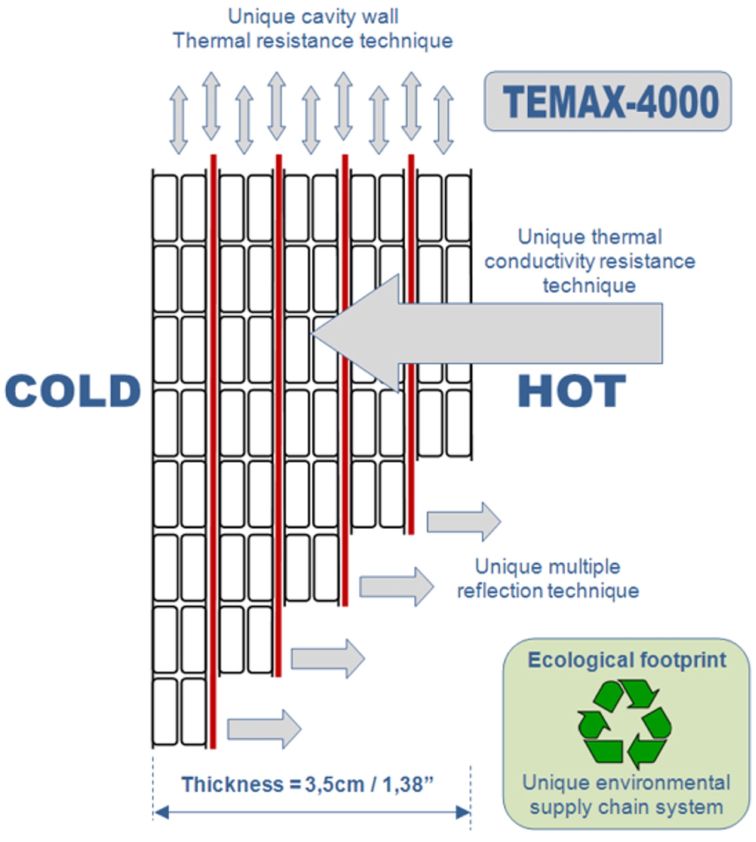

The Remax® insulation material is a unique engineered insulation material based upon air-thermal-conductivity (lambda 0,024W/m.K) and Polyethylene-LD-thermal-conductivity (lambda 0,33W/m.K). The Remax® material is thermally engineered according to ISO-6946 in which the engineered values are inclusive Rsi and Rse with horizontal transmission combined with the multiple Re values. The cavity wall technique which is integrated in some compositions was engineered with un-ventilated values.

Remax insulation foils

All the Remax reflective insulation foils are tailor made according to the required insulation capacity or needed thermal resistance.

Material thickness 3,5mm (0,137")

Material thickness 3,5mm (0,137")

(1x) Thermal bubble + (1x) Reflection

Material thickness 7mm (0,275")

Material thickness 7mm (0,275")

(2x) Thermal bubble + (2x) Reflection

Material thickness 12mm (0,472")

Material thickness 12mm (0,472")

(2x) Thermal bubble + (2x) Reflection + (1x) Foam

Material thickness 17mm (0,67")

Material thickness 17mm (0,67")

(2x) Thermal bubble + (2x) Reflection + (2x) Foam

Remax applications

Remax reflective insulation materials are used in thermal packaging systems such as cooler bags and thermal covers for the transport of time-temperature sensitive products. Remax reflective insulation materials are also used in building insulation in which they function as an additional insulating system for roof, wall and floor applications.

Remax manufacturing

Remax reflective insulation materials are manufactured by the company Krautz TEMAX in Europe and USA. All Temax products are tailor made and are aproved by Temax Quality Assurance according to the Q.A.P. "Quality Assurance Procedures" in regards to ISO-9001-2015.

MATERIALS - MANUFACTURING - RECYCLING

- TEMAX insulation

- REMAX insulation

- EPS Polystyrene

- BIO Thermal Packaging

Temax global protection

Temax global protection -

-